DSF-II

Mumbai, India

ONGC Mumbai India

Scope of Work

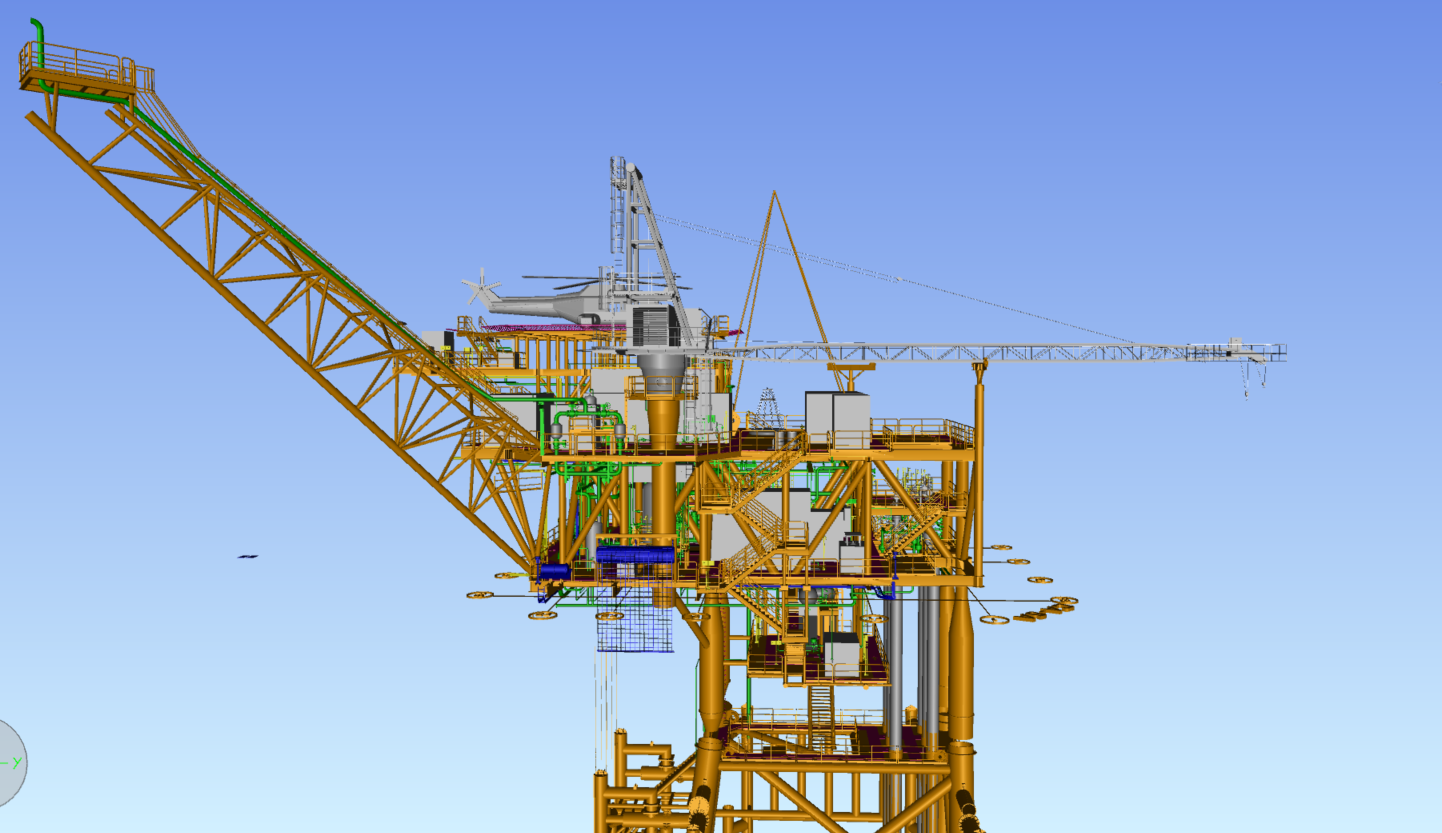

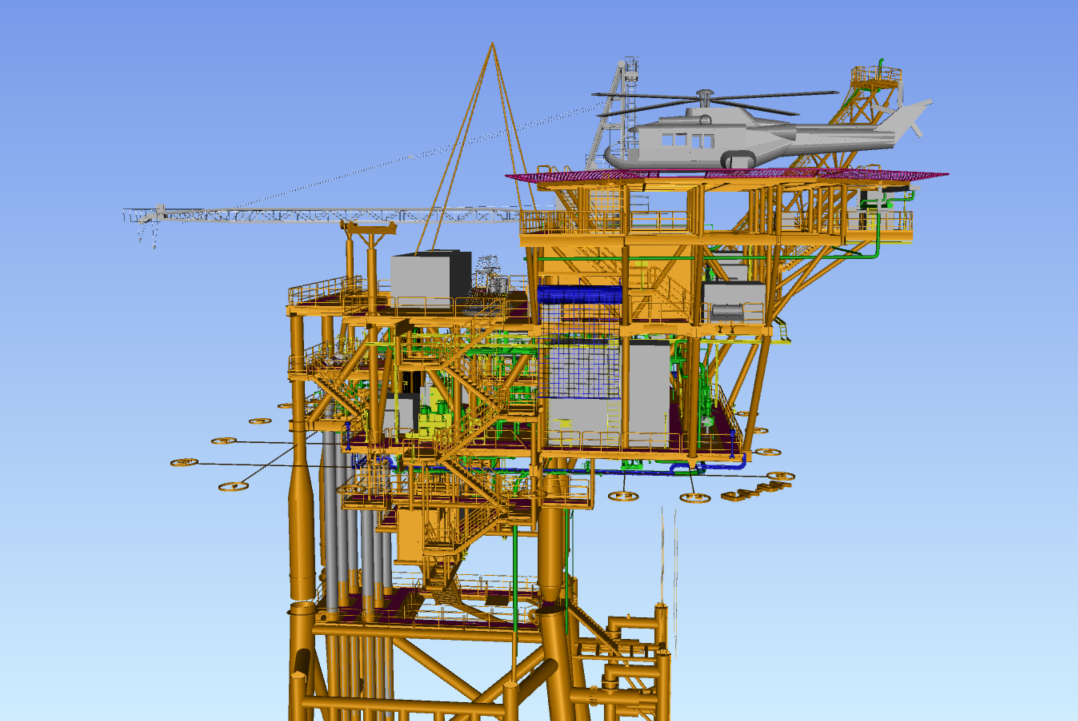

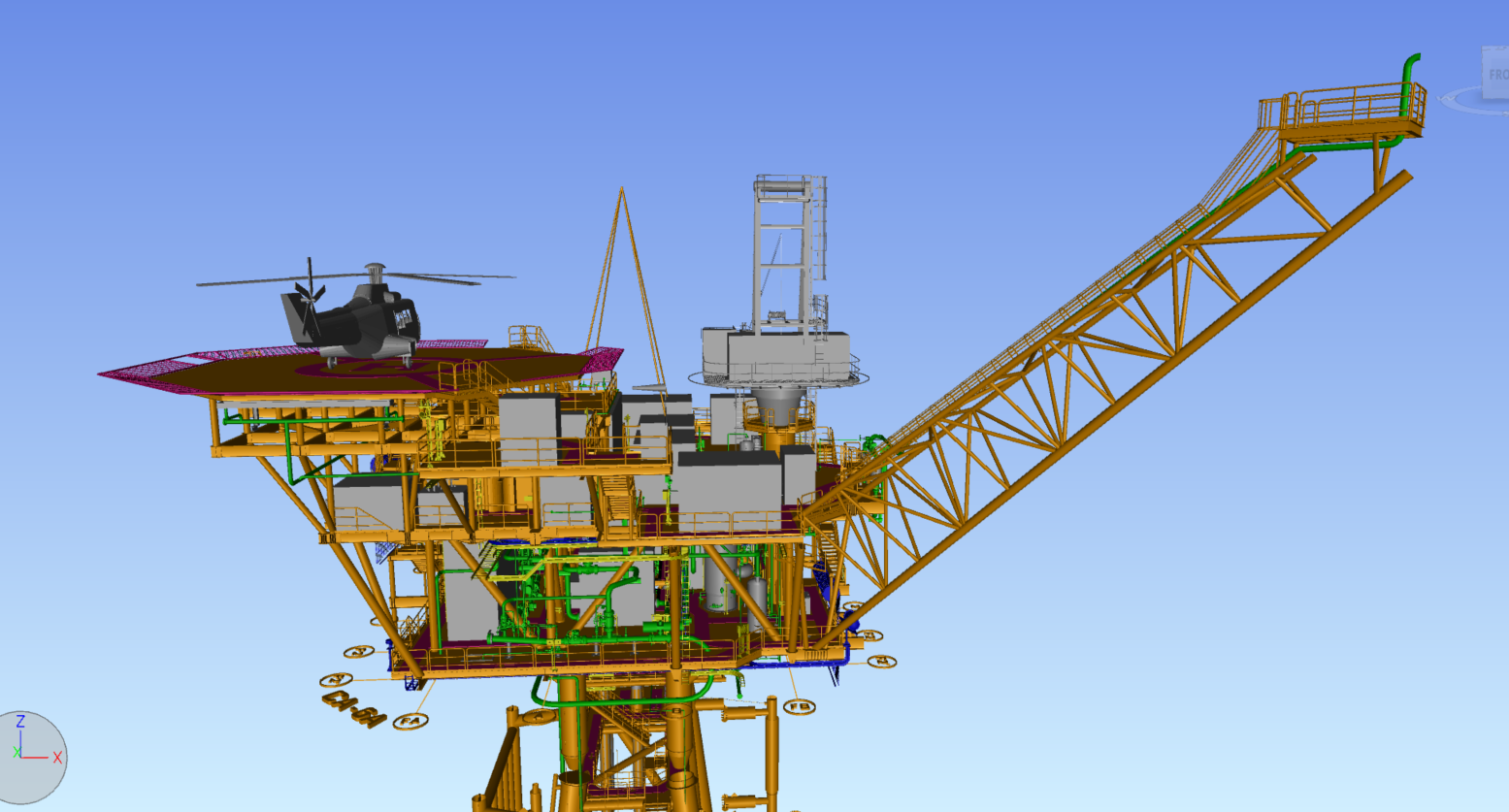

- Design and Detailed Engineering Development of six new wellhead platforms (CA-6A, SD-1A, SB-15A, D-33A, C-37A, NMT-A), including modifications to existing platforms (C24-RP, SB-14, SHG). The scope includes associated subsea pipelines and laterals, tie-in spools, and risers.

- Project Management and Execution Oversight End-to-end oversight of procurement for all materials; inspection, testing, and fabrication; load-out and tie-down; transportation and installation; post-installation and construction surveys; site acceptance testing; pre-commissioning and commissioning; as-built documentation; overall quality assurance and control; and compliance with all warranties and guarantees.

NET’s Role

NET has played a pivotal role in the successful execution of the project, contributing across key phases from conceptualization to commissioning. The scope of NET’s involvement includes:

- Plant Design and Engineering NET undertook the comprehensive design and engineering of the plant, ensuring that the layout, infrastructure, and integrated systems were meticulously planned and optimized to deliver operational efficiency, enhanced safety, and long-term scalability.

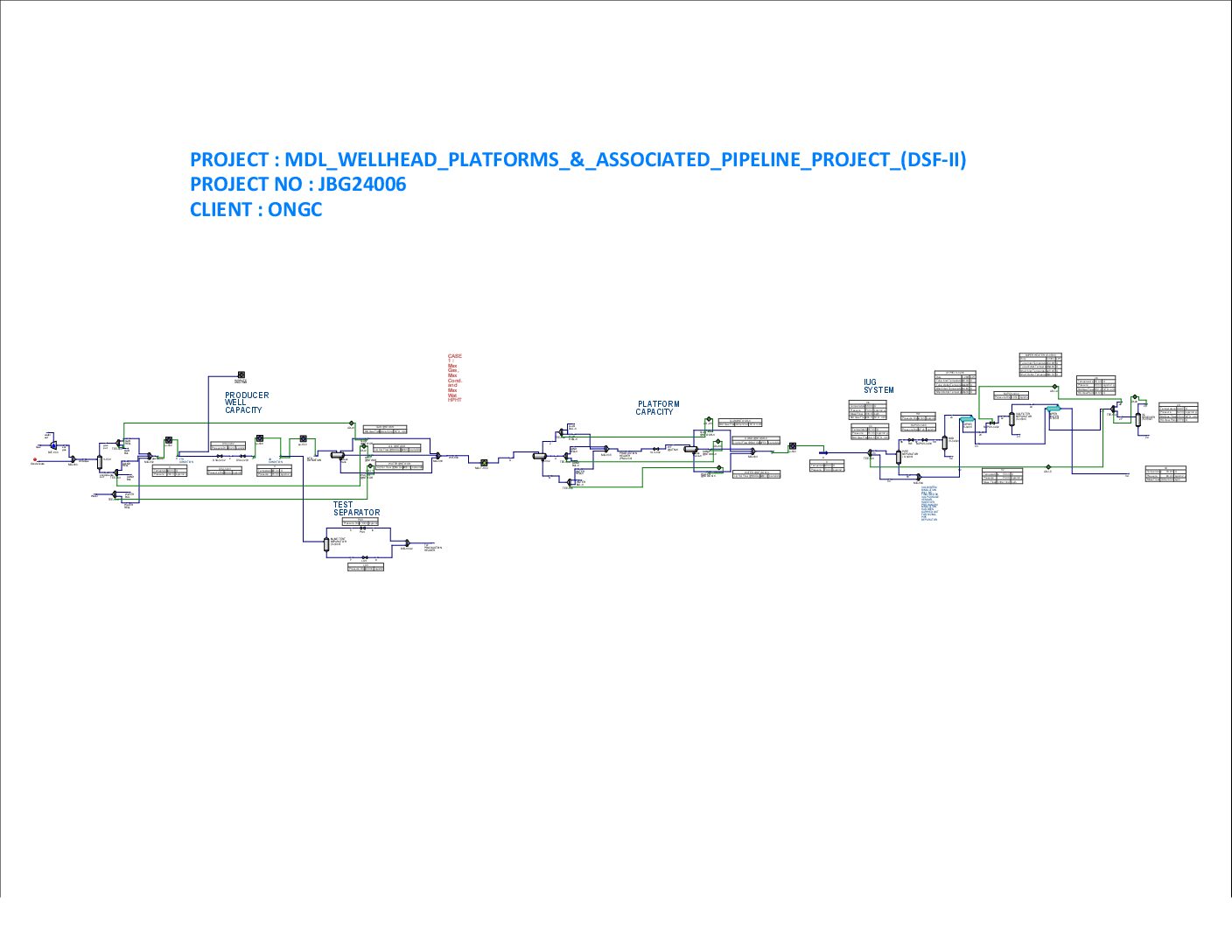

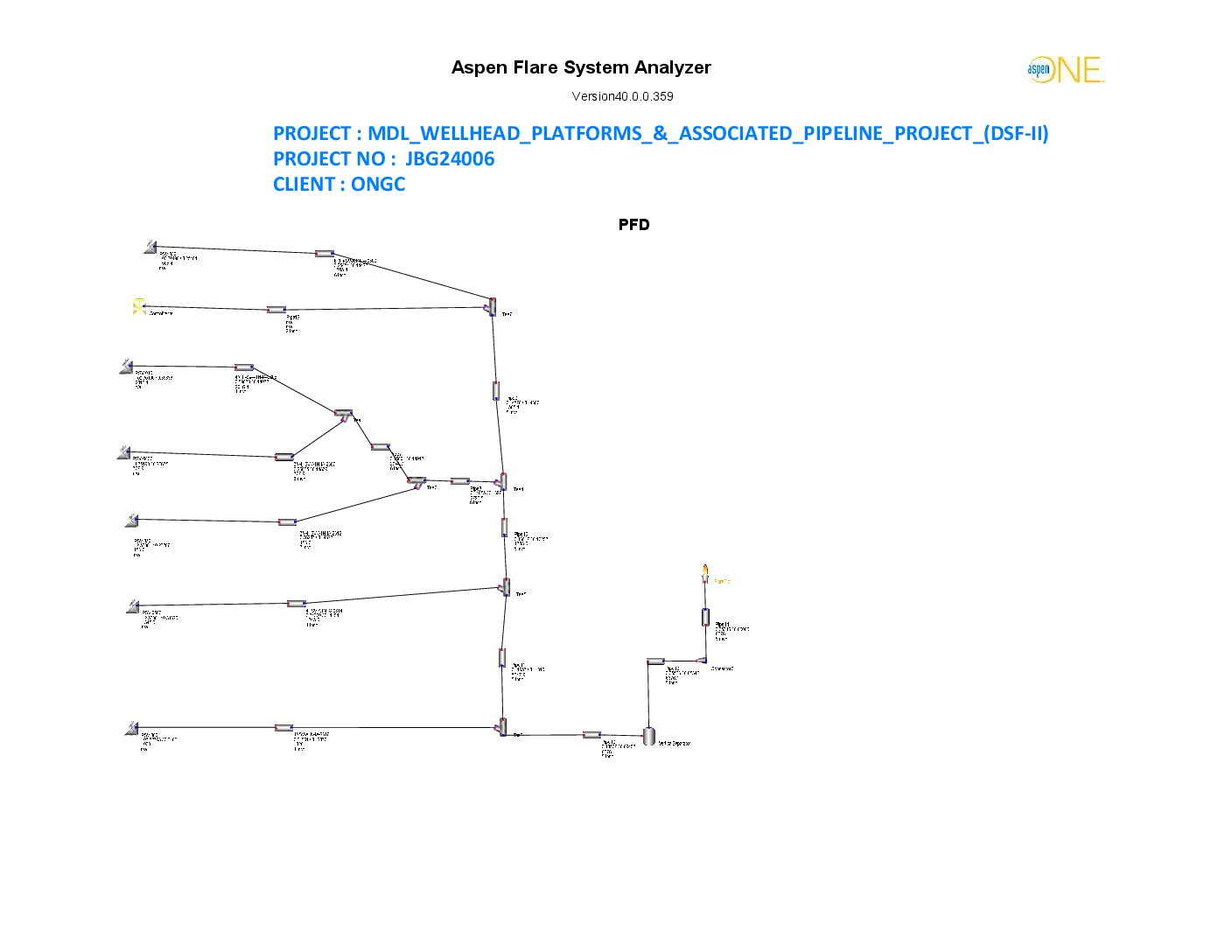

- Development of Process Flow Diagrams, Piping & Instrumentation Diagrams, and Equipment Selection NET was responsible for the development of detailed Process Flow Diagrams (PFDs) and Piping and Instrumentation Diagrams (P&IDs) to clearly define operational sequences, material flow, and system integration points. These diagrams served as the foundation for engineering design and process optimization. Additionally, NET led the evaluation and selection of suitable equipment and machinery, ensuring alignment with the facility’s technical specifications, performance objectives, and operational efficiency.

- Tendering and Vendor Finalization NET managed the tendering process, including preparation of technical specifications, evaluation of bids, and final selection of vendors. The focus was on ensuring cost- effectiveness, quality compliance, and timely delivery.

Current Progress

- Successfully conducted the 30% design review meetings for all designated platforms, marking a key milestone in the engineering workflow.

- Completion of Hazard and Operability (HAZOP) studies, ensuring preliminary risk assessments and process safety evaluations are in place for all units. Challenges

- Stakeholder Coordination

Challenges & Excellence

- Effective coordination among multiple stakeholders and contractors has been challenging, especially during the design revision and approval phases. These complexities have resulted in delays in receiving timely feedback, affecting the overall project schedule.

- Volatility in global supply chains has disrupted procurement timelines. Fluctuating material availability and logistical constraints pose a significant risk to meeting the project’s milestones.

- Adopt a proactive procurement strategy by identifying alternate suppliers, securing long-lead items early, and incorporating buffer periods into the project schedule. Regularly monitor market trends and logistics to adapt procurement plans dynamically.

- Integration with Existing Infrastructure

- Implement a centralized project collaboration platform to streamline communication and document sharing. Establish clear review cycles with defined timelines and assign dedicated interface managers to ensure accountability and faster resolution of comments.