Integrated Development of Cluster-I and GS29

Kakinada, Andhra Pradesh, India

Oil and Natural Gas Corporation Limited (ONGC)

Scope of Work

Phase-1: Pre-FEED (Conceptual)

- Data Review & Gap Analysis

Assess ONGC inputs, evaluate CPP’s existing/planned capacity, resolve interface issues, and address data gaps. - Field Development Planning

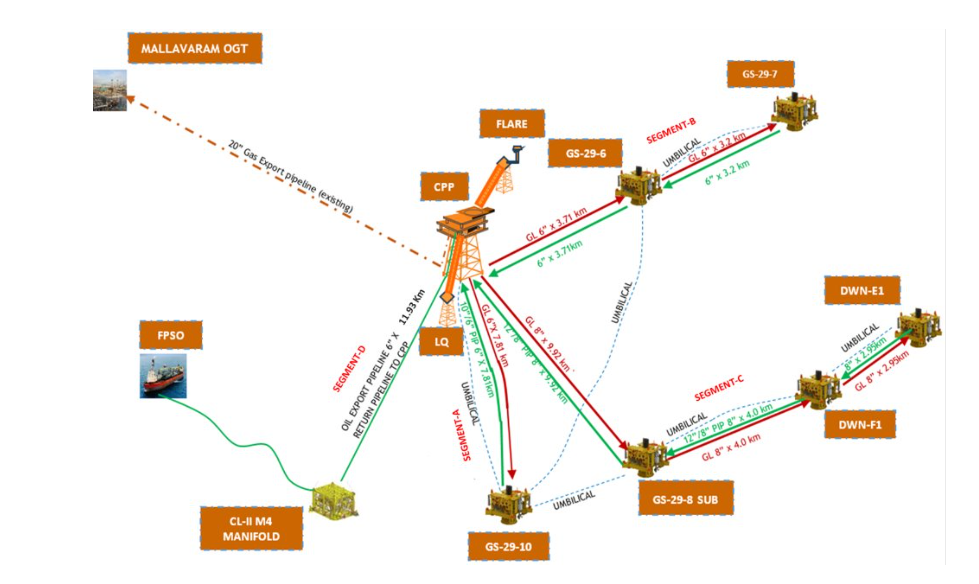

Finalize field architecture, develop preliminary P&IDs and layouts, and evaluate cost-effective alternatives and execution strategies. - Subsea Systems

Plan well re-entry, completion (CHGP), testing (SSTT, slick-line), and activation. Define control systems, evacuation strategy, pipeline layout. - CPP Facilities

Conceptualize process facilities and integrate with existing systems. Define CPP specs. - Oil Export Strategy

Define options for oil export based on technical and economic feasibility.. - Flow Assurance Analysis

Assessment and finalization of routing well fluid to the CPP, oil export, chemical injection requirements - Project Fundamentals

Prepare Basis of Design, cost estimates (±25%), schedule, risk mitigation plans, interface matrix, and contracting strategy. Ensure safety, environmental, and regulatory compliance.

Phase-2: FEED

Engineering and Tendering Support

- Preparation of FEED and technical bid packages for SURF components (umbilicals, risers, pipelines, subsea structures), CPP facilities.

- Supporting ONGC in tendering, bid clarifications, evaluations, and contract finalization.

Evacuation Option (FPSO)

- FEED and bid package preparation for FPSO-based evacuation scheme.

- Technical assistance through bidding and contract award.

Well Re-entry and Completion

- Technical bid package and tendering support for well re-entry, lower/upper completions, sand control, production testing, SSTT, and well activation.

NET’s Role

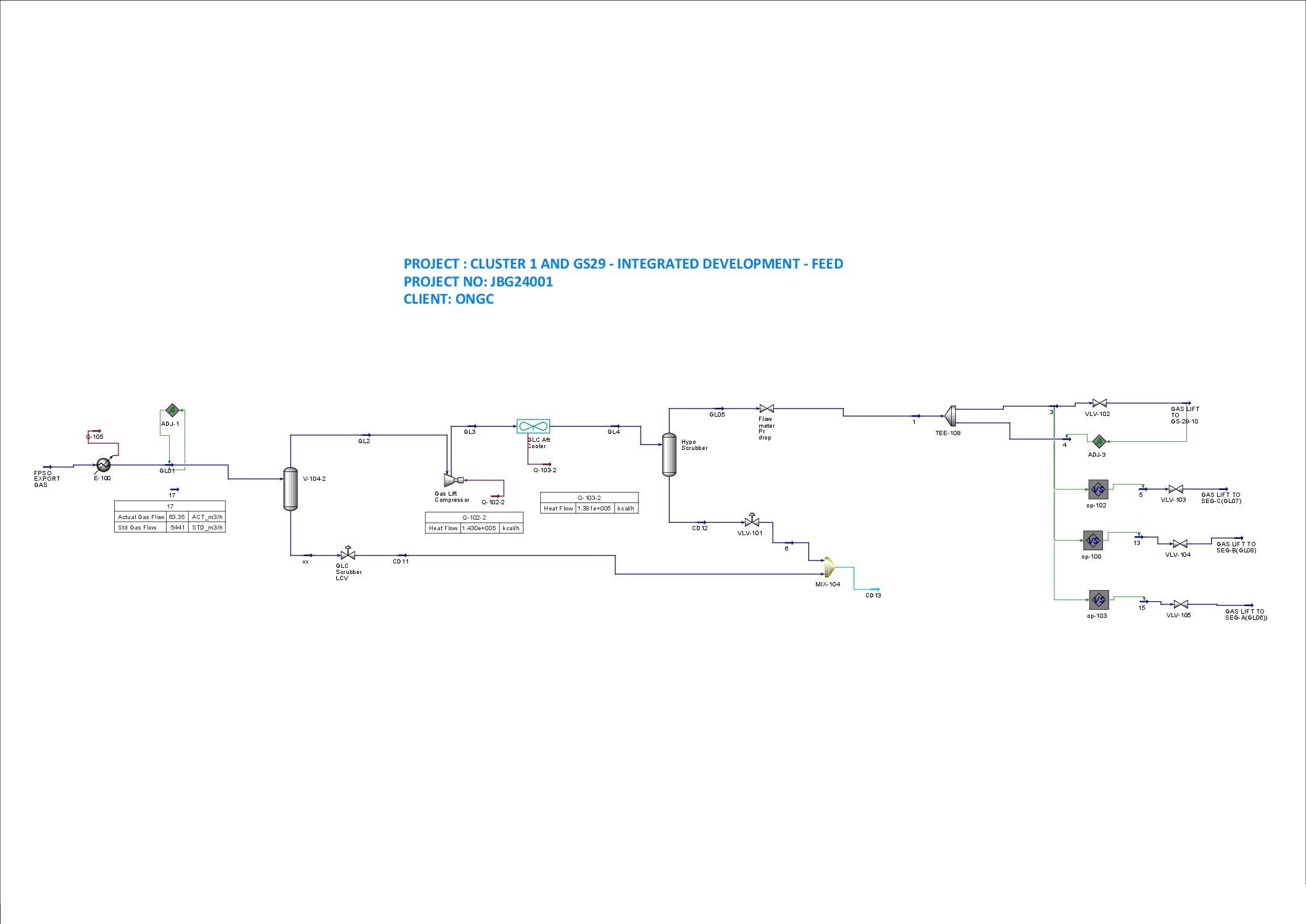

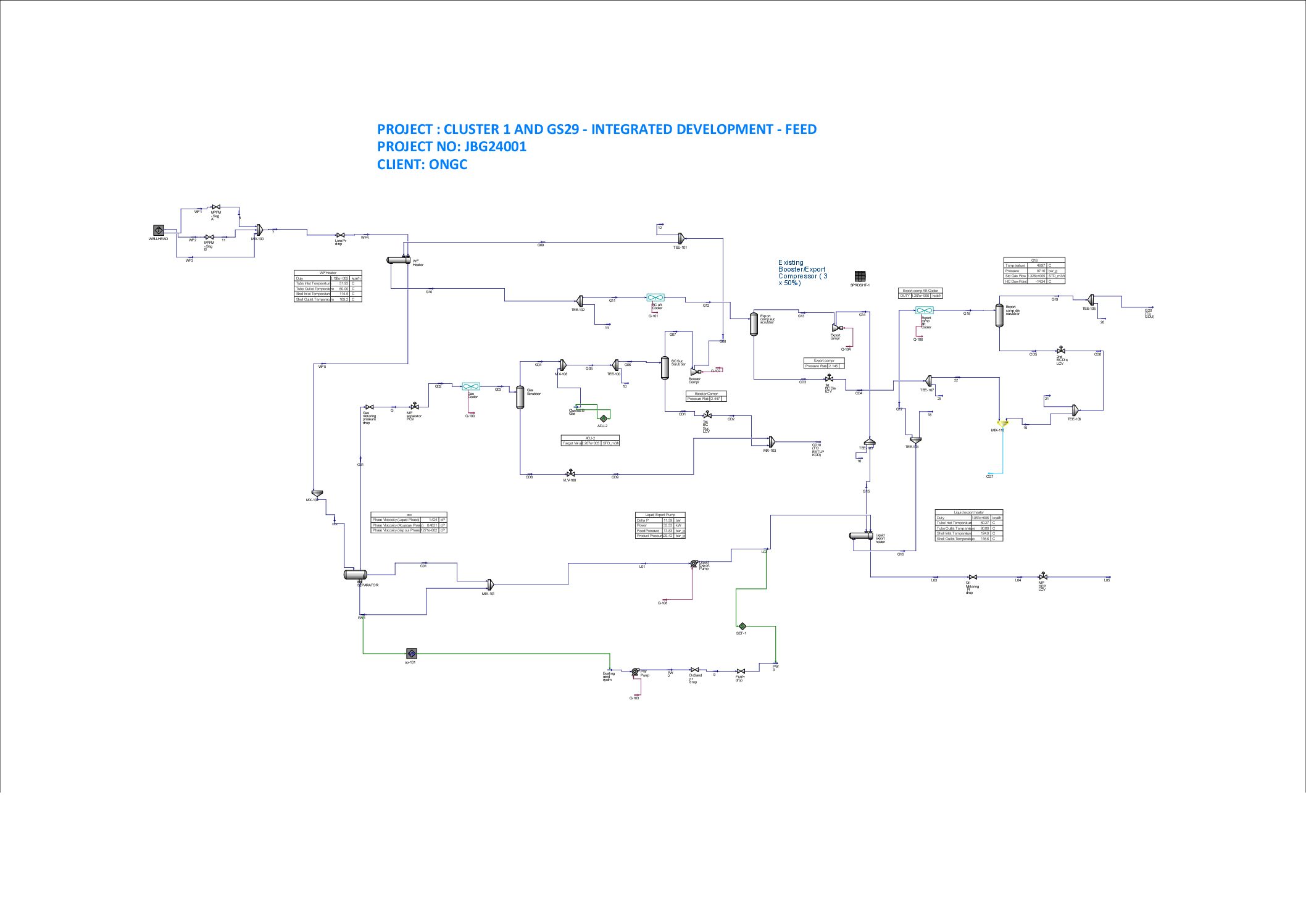

- NET’s role as consultant encompasses developing and evaluating multiple integration options for new wells with the existing Central Processing Platform to optimize design and operational efficiency. The adequacy of current CPP facilities and infrastructure are to be assessed, with recommendation of necessary upgrades and preparation of key engineering documents such as Process Flow Diagrams (PFDs), Piping & Instrumentation Diagrams (P&IDs), and equipment specifications.

- NET is responsible for designing additional processing units including separation, gas compression, chemical injection, and fluid handling systems. The scope includes thorough data review and gap analysis, resolving interface issues, and supporting subsea system design—covering well re-entry, completion, testing, and control system integration.

- NET shall prepare pre-FEED and FEED deliverables, including Basis of Design, cost estimates, risk mitigation plans, and tender packages, while providing engineering support during tendering and contract finalization.

- Throughout the project, NET shall ensure compliance with safety, environmental, and regulatory standards and coordinate with multidisciplinary teams and stakeholder communication to facilitate smooth project execution.